Product

MACHINES D'EMBALLAGE

- Permettent de former et de remplir des sachets et bouteilles en polyéthylène, en polypropylène, en complexes papier, en aluminium ou tout autres films thermoscellables.

Tous les composants en contact avec les produits sont en acier inox ou en PVC, conformément aux règles en vigueur.

Applications:

- Liquides : Sauce, Mayonnaise, Ketchup, moutarde, huile, eau plate, jus de fruits, lait, etc...

- Produits corrosifs: Acides, bases, organiques, eau de javel...

- Poudres : Sucre, sel, épices, poudre biologique, lessive, médicaments, Lait en poudre, ciment, gypse etc...

- Granuleux : Gros sel, médicaments, épices, graines, thé, etc...

- Morceaux : Sucre, bonbon, haricot, graines etc...

Price of the Product

Category of the Product

Company website

Our recommended products and services

-

-

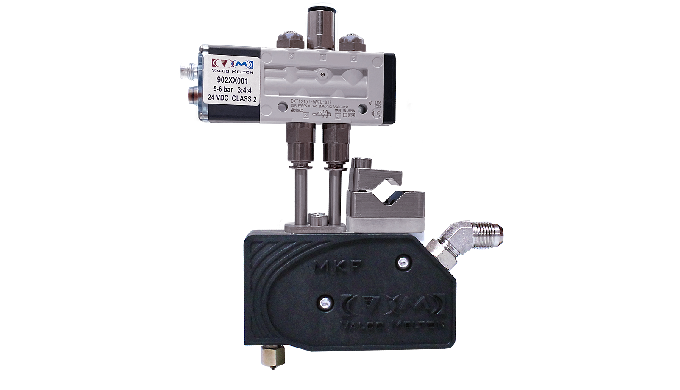

Guarantee easy and safe handling with Valco Melton’s MK-F Series Hot Melt Applicator, equipped with a specialty insulated cover. Its compact and efficient design provides optimal flexibility and easily adapts to customer needs, for easy installation and access in the most constricted spaces. Additionally, an integrated mini filter retains contaminants and maintains adhesive quality. • Minimal space required for installation and maintenance • Sharp cut-off for a clean application – no adhesive stringing • Specially insulated for safe handling • Zero cavity design – extremely fast and accurate patterns

-

Valco Melton has developed a new range of adhesive melters to suit any need in the packaging industry. This new generation of melters optimises the heating process and improves thermal insulation, thus minimising energy losses. • Its design includes different sizes and fusion capacities to suit each process. • Compatible with our previous systems and ranges, as well as other market standards. • Low-pressure pump available for processes that require working with low weights. • I/O signals included as standard. • Option of Ethernet communication kit with the main machine. Options / Upgrades: • FlexFlow Control controller to monitor adhesive consumption. It records the total adhesive consumption to avoid deviations from the set values and optimize the use of adhesive per product. • Possibility of incorporating VMConnect card and authorized connection through KubeCloud. This allows Valco Melton to monitor the correct operation of the system based on a number of key parameters. In this way, we can proactively offer recommended maintenance, eliminating unscheduled production stoppages.

-

Containers: - Container classification using a rotary feeder - Container classification via the infeed screw - Container transport using pucks for flexible production and fast conversion - Cycled container transport Shapes: - User-friendly, fast and primarily tool-free format change Design: - Simple assembly (plug and play) - low installation costs - Good visibility and accessibility - Compact design with low space requirement - Compact design with integrated control cabinet - Glue gap or tuck-in gap closure is possible - Modular machine design for maximum flexibility for future adaptations of products, packaging or functions - Few moving parts resulting in minimized sealing and maintenance costs

-